Application of Flextronics SD610 in hydraulic press

Ⅰ.The hydraulic press

The process of the hydraulic press is generally divided into short-range free-fall, slow-down, work pressurization, pressure holding, pressure relief return, floating crimping and ejection, etc. The working pressure and flow required for each action are different. In the hydraulic system of the dosing pump, the pump motor provides a constant flow rate at a constant speed, and the pressure and flow rate required for operation are regulated by the pressure proportional valve and the flow proportional valve by adjusting the opening of the pressure or flow proportional valve. To control the size of the pressure and flow. Excess hydraulic oil flows back through the overflow valve. This process is called high pressure interception. According to statistics, the energy loss caused by high pressure overflow is as high as 36% to 68%.

Ⅱ.The hydraulic press

The hydraulic press (a type of press) is a working medium through a special hydraulic oil. The hydraulic pump is used as a power source, and the hydraulic oil is passed through the hydraulic line into the cylinder/piston by the force of the pump, and then there is a cylinder/piston. Several sets of matching seals, the seals in different positions are different, but they all play a role in sealing, so that the hydraulic oil can not leak. Finally, through the one-way valve, the hydraulic oil is circulated in the fuel tank to make the cylinder/piston cycle work to complete a certain mechanical action as a kind of machine for productivity.

Ⅲ.Introduction to SD610 Electro-Hydraulic Servo System Introduction to SD610 Electro-Hydraulic Servo System

The electro-hydraulic servo system replaces the original heavy-duty pump-asynchronous motor system with the existing precision servo-hydraulic system to realize the on-demand supply characteristics of the hydraulic oil, so that the new hydraulic system has almost no overflow, and its composition Mainly by the following parts:

Drive

The drive uses a unique motor control algorithm for electro-hydraulic servo characteristics to achieve fast and smooth control of pressure and flow. It has a large margin design, high temperature environment is not running, and installation and debugging are convenient.

Among them, our company has developed a liquid-cooled series driver for the harsh working environment, which has the advantages of high temperature resistance, corrosion resistance and environmental impact.

2. Motor

The permanent magnet servo motor adopts the latest generation of rare earth permanent magnet material, which has small volume, low inertia, high performance, high efficiency, low noise, fast response, stable operation, high control precision, strong overload capability, and obvious power saving effect in continuous load. Features.

3. Oil pump

Electro-hydraulic servos can be used with gear pumps, plunger pumps and screw pumps due to different environments and requirements.

Gear pump: strong anti-pollution ability, long service life, good self-priming, simple structure and convenient maintenance.

Piston pump: high precision, good sealing and high working pressure.

Screw pump: low noise, high speed and small pulsation.

4. Pressure sensor

The pressure sensor can be divided into current type (4~20mA) and voltage type (0~10DC). When selecting, please refer to the sensitivity, offset, linearity, hysteresis and other parameters of the product, because the feedback signal directly affects the system. Performance, try to use high-precision, high-sensitivity, linearity of the brand.

ⅣSD610 electro-hydraulic servo system wiring diagram and site photos

![]()

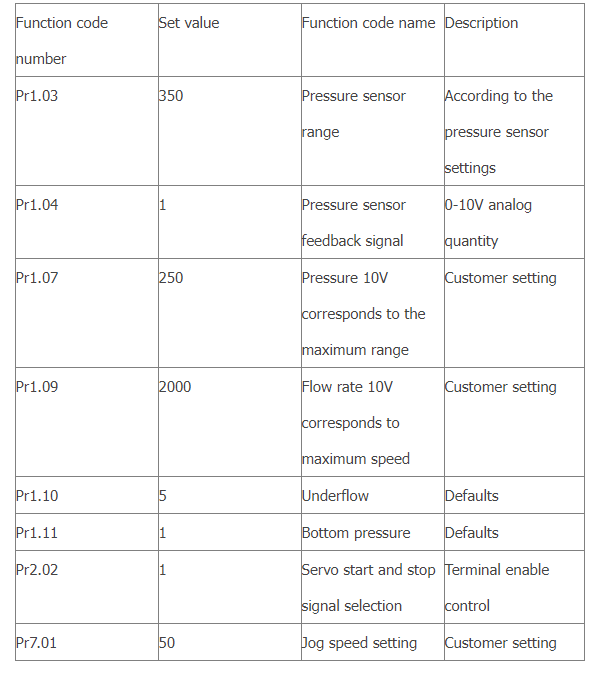

Ⅴ.parameter settings

1.Motor parameter self-learning

Ⅵ.Debugging instructions

1. When setting the parameters, press the JOG jog button to judge the motor direction. If the motor is reversed, please change the two motor wires arbitrarily, and then re-calculate the motor parameters. Remember to judge the motor direction first.

2. Monitor the values of U-01, U-02, U-03, U-04, U-05 and U0-12 during commissioning.

3. When setting the parameters, please turn the enable off to ensure that the green Run light is off, because the drive parameters cannot be set when the Pr2.02=1 terminal is enabled.

Ⅶ.Summary

The Flextronics SD610 electro-hydraulic servo system can detect the pressure and flow signals from the hydraulic system of the hydraulic press in real time, adjust the speed of the motor required for each working condition in real time, and let the flow and pressure of the pump output meet the needs of the system. In the state, let the motor run at a low speed, how much is really to be given, and the energy saving space is huge. Under the premise of satisfying customers' performance and stability, Flextronics SD610 electro-hydraulic servo system perfectly solves the requirements of cost, efficiency, oil temperature and precision of customers. Electro-hydraulic servo drive technology is the future development direction of hydraulic presses.

Related News

Engaging in Hydraulic Press ---Since 1996---

Service Support

Contact Us

Mr. Yang,Phone:0086-18033239126

WeChat:527700969

Address: 10#, Zhiye road, Songxia industrial park, Shishan town, Nanhai district, Foshan city, Guangdong province, P.R.C,528234.

Tel:0086-0757-85203155

Website:http://www.fshdltd.com

Official account

Copyright © 2023 Foshan Xinhongde Machinery Manufacturing Co., Ltd All rights reserved Powered by CEglobal Business license Privacy Policy