APPLICATION INDUSTRY

Application Industry

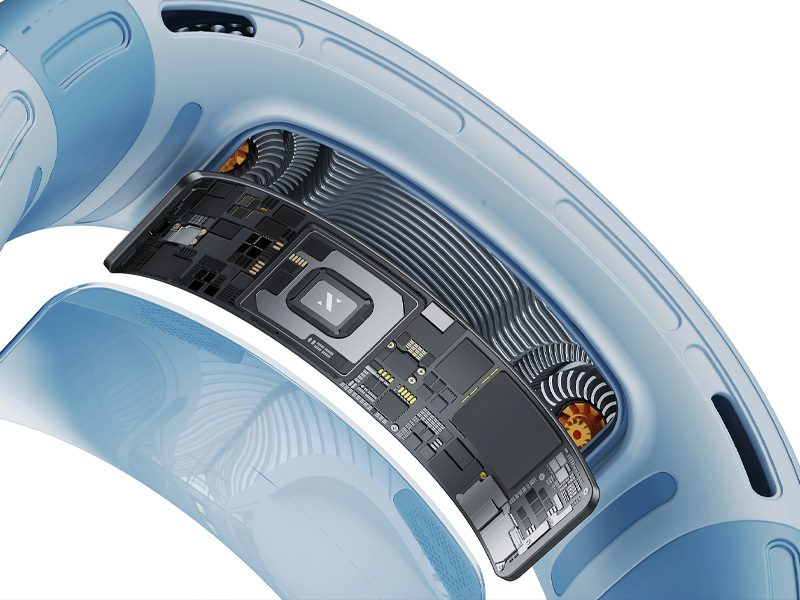

Flexible circuit board lamination packaging - Smart wearable sensor module

Bio-sensors (such as heart rate monitoring modules) in smart wearable devices require integration and packaging with multiple layers of flexible printed circuit boards (FPCs). A hot plate hydraulic press is used to apply a uniform pressure of 10 MPa at 80℃ to the PI substrate and conductive silver paste circuit layer for 120 seconds, achieving a bubble-free bonding of an ultra-thin stacked structure of 0.5 mm. Precision control within ±0.01 mm avoids circuit offset and ensures the stable signal transmission of the photoelectric sensors in Huawei/Xiaomi wristbands, increasing the yield rate to 99.3%.

Contact Us

Precision metal structural parts stamping - smart wearable device shell manufacturing

The metal bezels and cases of smartwatches/wristbands need to be lightweight and highly durable. Hydraulic presses, with a closing force exceeding 2000 tons and precision molds, are used to forge titanium and aluminum alloy structural components at temperatures below 500℃, achieving a tolerance control of 0.05mm. For example, the stainless steel case of the Apple Watch Series uses multi-station hydraulic progressive forming technology to shape the curved surface and precisely punch holes within a 20-second stamping cycle, ensuring both comfortable wear and reliable product structure.

Contact Us

Contact us

Address: No. 19, Science and Technology East Road, Songxia Industrial Park, Songgang, Nanhai District, Foshan City, Guangdong Province, China

Tel: 0086-0757-85203155

Mobile: 18033239126(Mr. Yang)

Fax: 0086-0757-85203166

Email: info@fs-hongdemachinery.com

Quick Navigation

©2025 Foshan Xin Hongde Machinery Manufacturing Co., Ltd. All rights reserved