APPLICATION INDUSTRY

Application Industry

Refrigerator compressor liner precision press-fit - core home appliance component

Hot forming of ultra-high strength steel chassis parts - New energy vehicle body structure

Ultra-precision straightening of hard disk read-write heads - cloud computing storage devices

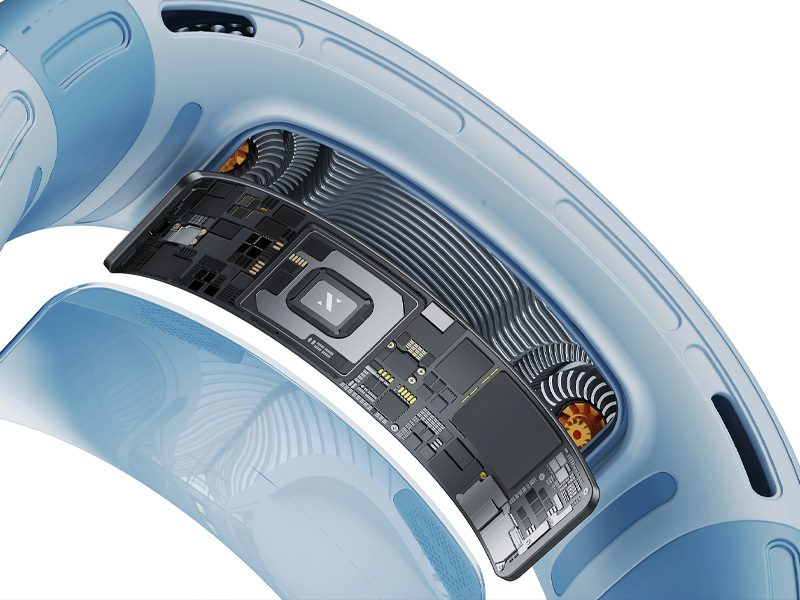

Flexible circuit board lamination packaging - Smart wearable sensor module

Server heat sink module bonding - Data center hardware production

Precision metal structural parts stamping - smart wearable device shell manufacturing

Contact us

Address: No. 19, Science and Technology East Road, Songxia Industrial Park, Songgang, Nanhai District, Foshan City, Guangdong Province, China

Tel: 0086-0757-85203155

Mobile: 18033239126(Mr. Yang)

Fax: 0086-0757-85203166

Email: info@fs-hongdemachinery.com

Quick Navigation

©2025 Foshan Xin Hongde Machinery Manufacturing Co., Ltd. All rights reserved